Thermosyphon technology is aimed at maintaining frozen ground states to support buildings, support structures on piles as well as keep ground frozen around transmission towers and pipelines, along railroad embankments and highways for their stabilization. The basis of thermosyphon thechnology is a heat transfer device (thermosyphon) which extracts the heat from the soil during winter and passes it to the environment. The significant feature of this technology is that it is passive and does not require any external power to operate.

The underlying mechanism behind all types of thermosyphones is identical. It is composed of sealed tube with a suitable fluid: carbon dioxide, ammonia or propane. The tube consists of two sections. The first one is located in the ground and is called an evaporator pipe. The second, known as the radiator section of the tube, is installed above ground level. When ambient temperature falls below ground temperature where the evaporator pipe is situated, then liquid vapour starts condensing in the radiator section. As a result, pressure is reduced and the liquid in the evaporator section boils and evaporates. This process results in heat transfer from the evaporator section into the radiator section.

Heat transfer by thermosyphon

Today several thermosyphon types exist:

1) Thermoprobe. A vertical thermosyphon tube which keeps ground frozen around the tube.

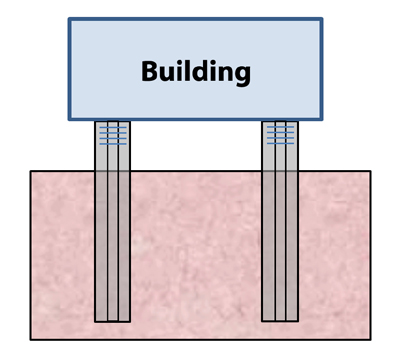

2) Thermopile. A vertical pile with integrated thermosyphon, designed to carry some load, for example a support for a pipe line.

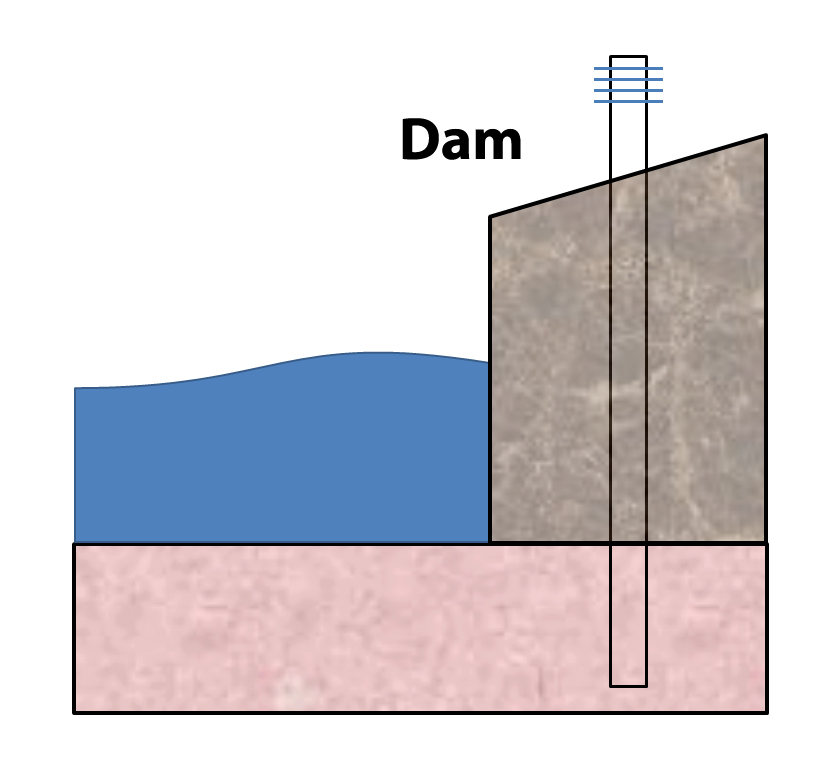

3) Depth thermosyphon. A long (up to 100 meters) vertical thermosyphon tube with an enlarged diameter. Such thermosyphon types are applied for ground freezing at great depth, to maintain frozen conditions in frozen-core dams, for example.

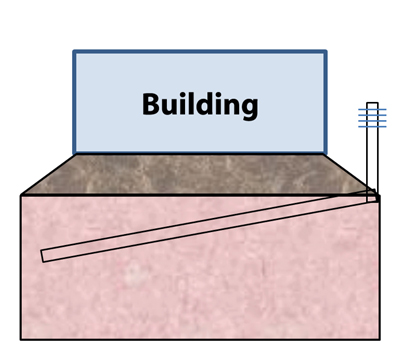

4) Sloped-Thermosyphon Foundation. This thromosyphon type, as opposed to the thermoprobe, is for installation of evaporator pipes with a 5% sloping gradient. In this case, it is possible to install sloped evaporator pipes straight under buildings raised on slab-on-grade foundations.

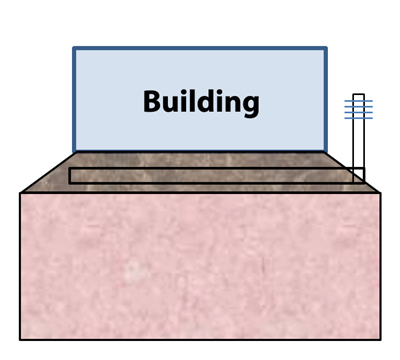

5) Flat Loop Thermosyphon Foundation. The main feature of Flat Loop TF is that it is installed completely horizontally on a level prepared granular base. In this case, building slabs are raised directly on the gravel bedding covering the insulation and evaporator pipes. The advantage of Flat Loop TF is the possibility to use it in two configurations: slab-on-grade foundations and сrawl-space foundations.

6) Hybrid Flat Loop Thermosyphon Foundation. This thermosyphon type is similar to Flat Loop TF, however it includes up to 30 interconnected vertical evaporator pipes alongside the horizontal evaporator pipes. The advantage of this thermosyphon type is to improve permafrost maintenance in the subgrade. The shortcoming of this thermosyphon type is that it makes repairs or changes to the services difficult.

Thermoprobe | Thermopile | Depth thermosyphon |

Sloped-thermosyphon foundation | Flat loop thermosyphon foundation | Hybrid flat loop thermosyphon foundation |